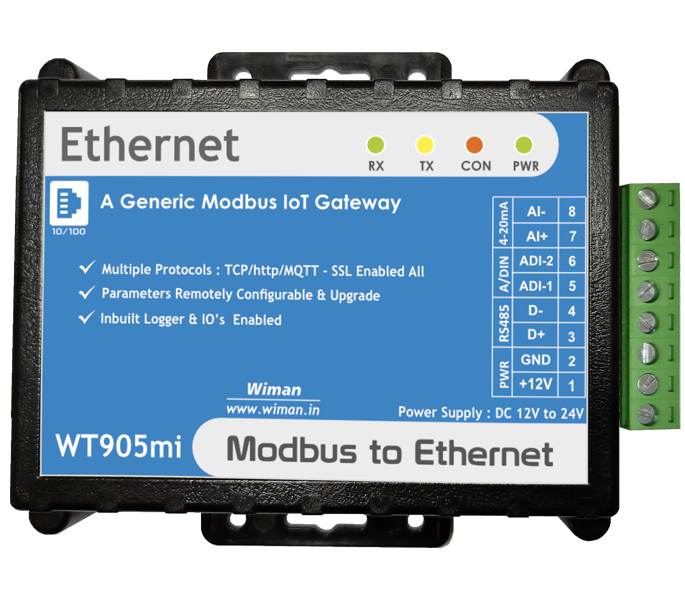

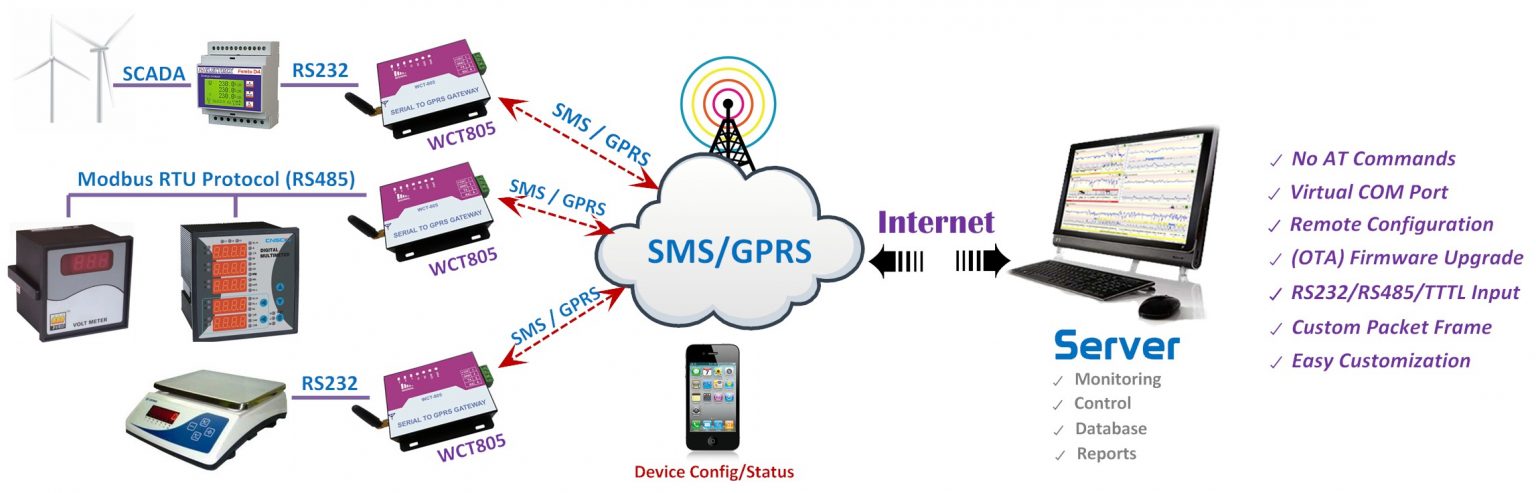

Our generic Modbus to Ethernet Gateway to fetch the Standard Modbus Slave device like Energy meters, Solar Inverters, PLC, Windmill, AMR, IO Modules, Flow Meters and more. The built-in smart data redundancy communication paths of Ethernet IP in RTU Gateway, the data would be guaranteed to transfer your centralized server. We also provide a Cloud-based Graphic interface (based on client requirements) to manage your device machines easily. Users can monitor and control the Slave and I/O data of RTU devices

Ethernet Gateway Highlights

- Intelligent Modbus, IO, Data Logger, Ethernet/LAN Connectivity

- 1 x RS-485 port for Modbus, 1 x Utility port for Configuration

- Configure and Read Multiple Slave IDs, Selectable Register Address data.

- Parameter Data type, Byte Swapping Conversion and Scaling factor enabled.

- Transparent Modbus or Device Inbuilt Polling – Formatted to (ASCII/HEX/RawHEX)

- Smart Inbuilt Data Logger works during Network and Server Disconnection

- Logger Sends offline data once Network and Server Connected

- Authorized numbers list for command and Configuring.

- Configurable TCP/Http/MQTT/Https Mode, GET/POST Methods

- Configurable CSV/JSON Format for Parameter Packetization

- Remote Configuration through Web Portal/Server IP Commands

- Additional 2 x Digital/Analog Chanel (0 to 24V), 1 x 4 to 20mA Chanel.

- OTA (Over The Air) Firmware upgrade, Device Configuration update.

- LED indicators to provide GSM, GPRS, Signal, Modbus Tx/Rx COM Status.

- Configurable Server Connection: Connects on Demand or Always Connected.

- Keep Alive command to maintain socket connection

Application Segments

- Automatic Meter Reading

- Solar Inverter Monitoring and Control

- Generator Monitoring and Control

- Energy Monitoring and Control

- Fault Indicators

- Temperature Alerts, Indicators

- Pump Control, Flow Measurements

- Water Level Monitoring and Control

- Home Automation

- Windmill, SCADA, Data Exchange

- Central Monitoring and Control Systems

- Base Station, ATM Monitoring and Control